12/07/2018

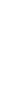

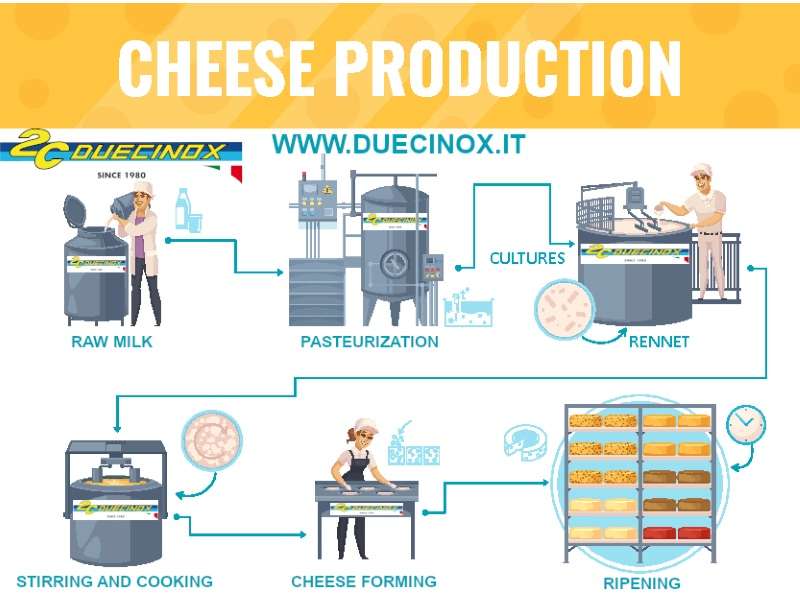

The steps on how to make cheese. The artisanal cheese production in the mini dairies can be essentially summarized in the following steps:

MILK RECEIPT: the milk arrives at the cheese factory when it’s refrigerated or just milked if the stable is adjacent to the processing place.

MILK THERMICAL TREATMENT. On the basis of the cheese type to be produced (fresh or matured), the milk can be thermised or pasteurized (the temperature is in relation to the treatment time, for example 72°C for 15 seconds).

This process can be done or in a plate pasteurizer or in proper polyvalent cooking vats with control of the executed thermal cycle.

MILK PROCESSING INTO CURDLING: FERMENTS AND RENNET ADDITION. After the thermal cycle, ferments can be added to milk according to the dairy product to be got.

Once they made their action, the liquid or plant rennet is added to get the curd. (It’s specified that the coagulation of casein, a milk protein, can be obtained also by adding a coagulant (rennet-based) as well as by adding rennet, or through an acid coagulation).

PROCESSING THE MILK INTO CHEESE: after the rennet action the curd is processed with cut, which can be done with mechanized system or manually with a curd knife or a lyre. The cut is necessary to purge the whey from the curd and the dimension of the granules changes according to the cheese type (soft, semi-hard, hard) which is intended to get.

Afterwards, it’s possible to make a second cooking processing of the curd depending on the cheese type.

CHEESE MOULDING AND MATURATION: After having been processed, the curd can be put in proper moulds to be moulded and to facilitate the purge of the whey. In some types of cheese a mechanical pressing action can be required to facilitate this step.

After this phase, before packaging stewing and salting can be made (for fresh cheese), maturation can be made in a proper place for matured cheeses. The maturation time requires particular temperature, ventilation and humidity conditions according to the cheese type and can never last less than 60 days.

This phase is important because cheese can acquire all those physical, microbiological and organoleptic transformations which allow to get the composition of distinctive aromas, smells and tastes.

For further information on dairy processing or to make use of an advice with our experienced dairyman, contact us.